IO-Link is an open standard of communication that allows for the easy connection and setup for systems of sensors and actuators.

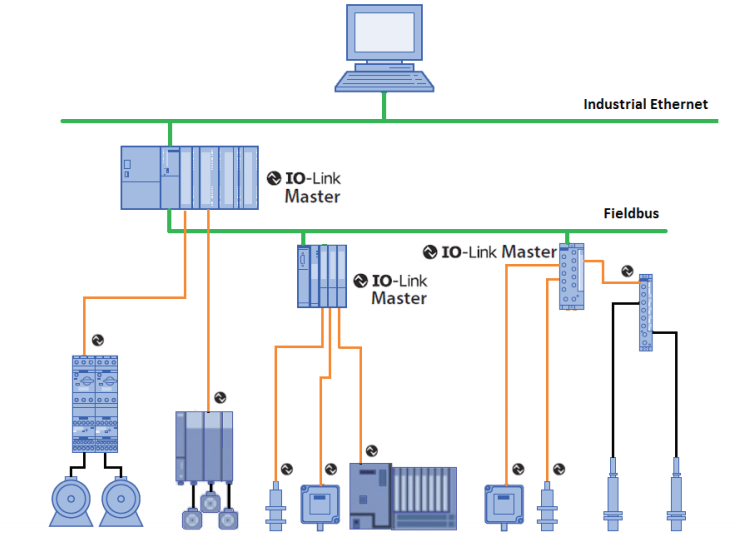

IO-Link systems are generally composed of two basic components:

- IO-Link Master

- IO-Link Devices

The master block communicates with all of the various IO-Link devices attached to it, and is generally controlled by a PLC over a fieldbus communication protocol such as EtherCAT or Profinet.

IO-Link devices are connected directly to the master using standard cabling such as M12 3 or 5 conductor cables.

There are many kinds of IO-Link devices such as Sensors, RFID Readers, Valve Banks, and Digital IO modules.

Some of the major benefits to IO-Link include simple wiring, consistent communication, and in-depth parameter control.

Simple Wiring

The IO-Link standard specifies the pin assignment of masters and devices, as well as how the devices must interact. This allows for quick and easy wiring of the system, and ensures compatibility irrespective of the individual product manufacturers.

Consistent Communication

IO-Link devices allow access to all of their internal data, including device information, process data, and diagnostic data. This data is then presented in a reliable way allowing for fast and consistent communication. Having the diagnostic data available also allows for quick troubleshooting and easy preventative maintenance.

In-Depth Parameter Control

The parameters that govern how the IO-Link device works are easily controllable over the IO-Link network, reducing set up time. The system can also be set up to automatically re-upload parameters to a device if it has to be replaced, significantly reducing downtime.