Oriental Motor Virtual Showroom

Discover Oriental Motor’s latest motion control solutions ranging from standard AC gear motors to the advanced AlphaStep hybrid stepper motor AZ Family of products. Explore how the products in our wide line-up are incorporated into the latest trending...

New AZ Series Drivers Available with PROFINET Communication

Oriental Motor is pleased to announce the latest addition to the AZ Series family of single axis stored data drivers, which now includes AC and DC input. Both input types are now available with PROFINET communication. The AlphaStep AZ Series stepper motors offers high...

Mac Valves for Hazardous Locations

We are pleased to announce a major expansion to our list of Hazardous Location offerings with the addition of the D-Coil configuration. This release grew from the need for a hazardous location Pulse Valve. Careful planning and consideration by MAC’s Product...

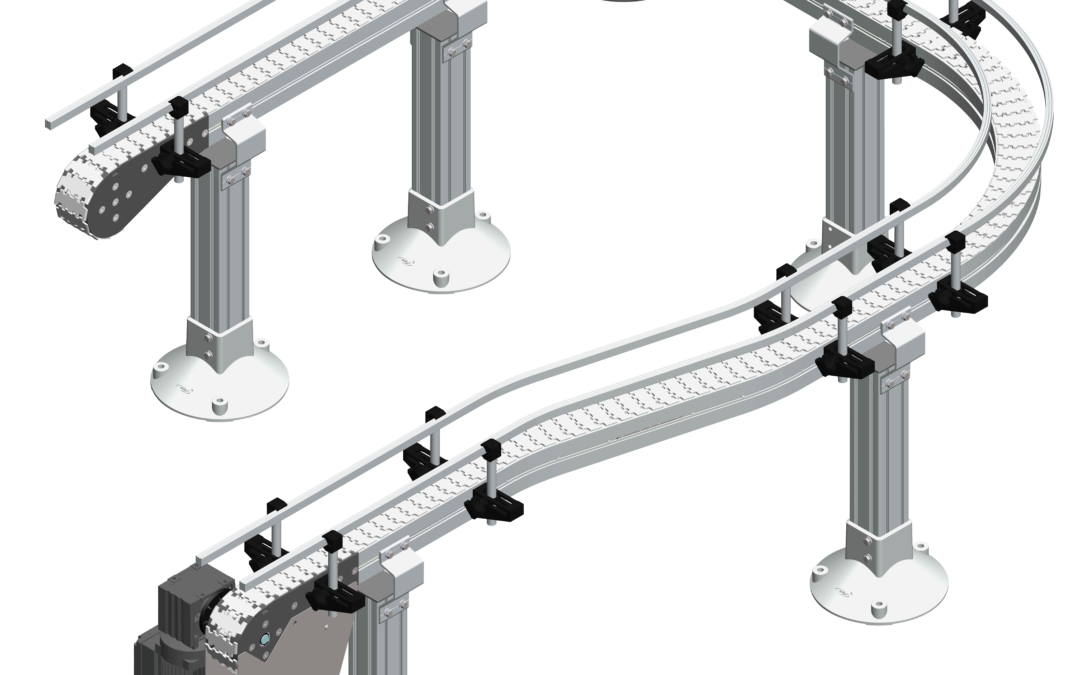

Introducing the new Flextrac Conveyor from QC Conveyors

Overview Modular construction allows infinite configurations for nearly any factory automation application Take advantage of unused vertical real estate with gripper elevator or alpine conveyor options Available with aluminum or stainless steel construction Variety of...

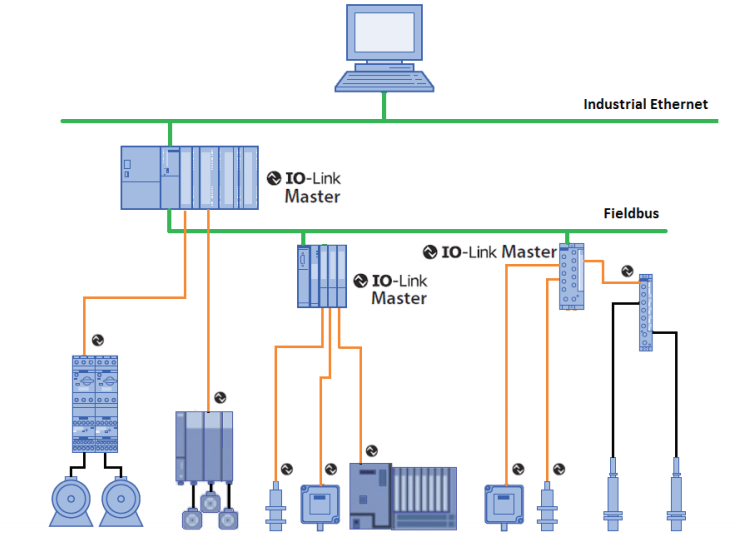

IO-Link Systems Overview

IO-Link is an open standard of communication that allows for the easy connection and setup for systems of sensors and actuators. IO-Link systems are generally composed of two basic components: IO-Link Master IO-Link Devices The master block communicates with all of...